| Phone: |

+420 54949 8217, +420 541 149 223 |

| E-mail: |

,

|

| Office: |

|

Research areas

-

Plasma processing of materials, plasma diagnostics, process monitoring and simulations

-

Functional plasma polymer coatings

-

Inorganic and hybrid (organic/inorganic) coatings and nanomaterials

-

Carbon nanostructured materials and their functionalization

-

Development of methods for the characterization of optical and mechanical properties of materials

-

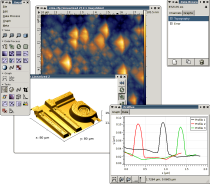

Development of the scanning probe microscopy (SPM) data analysis software, Gwyddion

Main objectives

The aim is to develop procedures for plasma processing of materials (plasma enhanced chemical vapor deposition - PECVD, plasma polymerization, plasmachemical synthesis of nanomaterials, plasma treatment and reduction) enabling the preparation of advanced materials and surfaces with additional functionalities and applications in sensing, tissue engineering, tribology, optics, smart textiles, batteries etc. One of the objectives is the understanding of interaction of reactive plasmas with a solid surface using thin film and surface characterization methods, plasma diagnostics, process monitoring and simulations. Additionally, our goal is to further develop physical methods and software for the characterization of materials, namely for the characterization of optical and mechanical properties and scanning probe microscopy.

Content of research

The research group operates on the premises of Department Physiscal Electronics and CEITEC Core Facilities. All the related publications can be found here (for full texts log in as guest).

Plasma processing of materials, plasma diagnostics, process monitoring and simulations

We develop and investigate low and atmospheric pressure plasma processing of materials. The understanding of the processes and interaction of plasma with surfaces is achieved by plasma diagnostics, process monitoring and simulations of related phenomena (electromagnetic field, gas flow, heat transport, plasma).

-

Numerical simulation

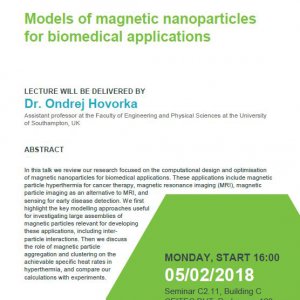

In our numerical models, we focus exclusively on plasma devices which have direct material or biomedical applications. We simulate plasma in close-to-real geometries in relevant gas mixtures. This does, sometimes, pose a big challenge because the coupling of the plasma, the gas dynamics and mixing and the electromagnetic field is very strong. The numerical modelling is, always, complemented with plasma diagnostics in order to verify the validity of our models. The most interesting models that we have developed include:

-

Coupled model of gas dynamics and the electromagnetic field in a microwave plasma torch operating at the atmospheric pressure in an inhomogeneous argon/hydrogen mixture.

-

Gas dynamics model of gas flow and heat transfer in a radio-frequency jet for bioapplications.

-

A model of gas dynamics and precursor consumption in a dielectric barrier discharge with the aim of gas supply optimization.

-

Currently, our main focus lies on self-consistent modelling of atmospheric discharges with bioapplications.

-

Plasma diagnostics

Knowing the conditions in the plasma discharges, especially the gas and electron temperatures and the electron density) is absolutely crucial for transferring our plasma processes to different setups or for upscaling them. In addition, measurements of plasma properties are very useful for validation of the numerical models developed in our group. So far, we have employed the following techniques to characterize our discharges:

-

Optical emission spectroscopy for electron denisty and gastemperature measurements.

-

Thomson scattering for electron density and temperature measurements and Rayleigh scattering for gas temperature measurements (in collaboration with Technische UniversiteitEindhoven).

-

Laser schlieren deflectometry for gas temperature measurement.

-

Capacitively coupled radio frequency (RF) discharges

-

Cold RF plasma jet

-

Dielectric barrier discharges (DBD)

-

Microwave plasma torch

Microwave plasma torch is atmospheric pressure device that provides high temperature, electron and energy density. In applications it is most suitable for conversion and synthesizing processes where it can achieve full breakdown of the precursor molecules to active radicals. We have successfully utilized this device for synthesis of nanoparticles and nanotubes and also studied by diagnostic methods and modeling.

-

Glide arc

The glide arc or gliding arc is a type of a plasma discharge, where the arc channel is moving along slanted electrodes. When external forces (buoyancy, gas flow) act on the plasma channel, it is pushed from this optimal position. The discharge channel starts to glide and consecutively changes its properties from the ones nearly identical to a standard arc discharge at short channel lengths to a non-equilibrium plasma at longer channels. The non-equilibrium stage begins when the length of the plasma column exceeds its critical value and heat losses from the plasma begin to exceed the energy supplied by source. The maximum length of the glide arc channel is related to the supplied voltage. After the quenching of one discharge at maximum elongation a new discharge appears at minimal electrode distance and the whole evolution is repeated. Advantageous properties of the glide arc plasma can be used for various applications such as decontamination, methane transformation or CO2 dissociation. Reference:

Hypergravity effects on glide arc plasma

Functional plasma polymer coatings

The plasma (co)polymerization is applied for a surface modification by coatings containing (bio)active groups (carboxyls, amines, ...). We develop plasmachemical processes that utilize non-toxic monomers. The coatings can be applied to different substrates because the processes take places at temperatures closed to the room temperature. The coatings are tested in sensors, for immobilization of biomolecules and for the modification of biodegradable electrospun polymer nanofibers aiming at the applications in tissue engineering.

-

Plasma polymerization of cyclopropylamine

-

Preparation of immunosensor with the help of plasma polymerization

-

Modification of polycaprolactone electrospun nanofibers

Hard and hybrid (organic/inorganic) coatings

Organic/inorganic organosilicon coatings with tuned hybrid structure are deposited by PECVD from organosilicon monomers (e.g. hexamethyldisiloxane - HMDSO) in low pressure RF discharges, atmospheric pressure DBD and RF plasma jet. We develop and investigate hard coatings based on diamond like carbon (DLC) prepared by low pressure PECVD.

-

Organosilicon protective films prepared by low pressure PECVD

-

Organosilicon films prepared in atmospheric pressure discharges

-

SiOx and nitrogen doped DLC films

Metal oxide coatings and nanomaterials

Very thin films of TiO2, HfO2 and other oxides are prepared by atomic layer deposition (ALD) or plasma ALD. Additionally, we investigate the structure of TiO2-based ternary oxides prepared by PECVD. In MW torch, a fast synthesis of iron oxide (maghemite, hematite) nanoparticles and nanostructured coatings can be tuned to desired applications including in-flight coating of nanoparticles for a core-shell structure.

-

ALD and plasma ALD of oxides

-

Ab-initio calculations of structure and optical properties of TiO2-based ternary oxides and HfO2

Carbon nanostructured materials and their functionalization

Carbon nanotubes (CNTs) and graphene nanowalls are synthesized directly on the functional devices, e.g. sensors, using the MW plasma torch or by CVD using iron catalytic nanoparticles synthesized in the torch. Graphene is grown on copper foils by CVD. The CNTs or graphene are functionalized by plasmachemical method for enhanced sensing properties, imobilization of biomolecules, better dispersion in liquids (e.g. for spraying) or improved dispersion and covalent bonding in polymer matrixes (for composites). Plasmachemical modified carbon nanomaterials can find applications in smart textiles, multifunctional polymer composites, (bio)sensors, supercapacitors, batteries etc.

-

Growth of CNTs in MW torch

-

Polyurethane composites filled by plasma-functionalized CNTs

-

Field emission pressure sensor based on CNTs grown in MW torch

-

Modifications of working electrodes of electrochemical sensors using CNTs and plasma treatment

-

Gas sensors

Enhanced adsorption properties of carbon nanomaterials make it possible to create novel gas sensors with improved performance. High surface area of porous CNTs and carbon nanofibers increase the response of the gas sensors. Unique and fast plasma-assisted technique of making of the gas sensors based on carbon nanomaterials (carbon nanotubes, carbon nanofibers, graphene etc.) was created to investigate and produce high quality devices. Advantages of the gas sensors based on carbon nanomaterials:

-

Excellent sensing properties allow to use the sensors at room temperature;

-

Low detection limit (e.g. lower than 10 ppm);

-

Possibility to engineer the sensing properties precisely;

-

Possibility to use the gas sensors for a wide range of industrial and toxic gases or gas mixtures (CO, CO2, CxHy, NH3, NO2 etc.).

Development of methods for the characterization of optical properties of materials

The optical characterization of thin films and surfaces is performed by the combination of ellipsometric and spectrophotometric measurements in the wide spectral range. We develop own software (newAD) for the solution of advanced and complex problems. The characterization provides information not only about the thickness and optical properties (refractive index and extinction coefficient) but also about non-uniformity, inhomogeneity, existence of interlayers, roughness, changes in chemical composition and electronic band structure.

Development of methods for the characterization of mechanical properties of materials

The advanced studies of mechanical properties of thin films and nanomaterials is carried out by instrumented micro/nanoindentation and nanoscratch tests. The complex analysis of relation between nanoindentation response and material structure is performed for thin films, multilayered and nanocomposite materials. Recently, the measurement in liquids for the samples with potential bioapplications and the measurements at the temperatures up to 800 oC are investigated.

-

Hysitron 950 TI

The Hysitron TI 950 TriboIndenter is a nanomechanical test instrument with a high degree of sensitivity and excellent performance. Its Advanced Control Module improves the precision of feedback-controlled nanomechanical testing, provides dual head testing capability for nano/micro scale connectivity, and offers very good noise floor performance. Several different nanomechanical testing techniques are currently possible, making the TI 950 nano-indenter system an effective nanomechanical characterization tool for a wide range of applications.

Hysitron's TI 950 TriboIndenter Features:

-

Quasistatic nanoindentation – Measure Young’s modulus, hardness, fracture toughness and other mechanical properties via nanoindentation.

-

Scratch testing – Quantify scratch resistance, critical delamination forces, and friction coefficients with simultaneous normal and lateral force and displacement monitoring.

-

Top-down optics – High- resolution, color CCD camera for individual structure identification and coarse test positioning.

-

SPM imaging – In-situ imaging using the indenter tip provides nanometer precision test positioning and surface topography information

-

Dual head testing capability for true nano/micro scale connectivity

-

Active vibration isolation systemproviding environmental separation

Available modules:

-

nanoDMA – Investigate time-dependent properties of materials using a dynamic testing technique designed specifically for polymers and biomaterials

-

Modulus Mapping – Obtain quantitative maps of the storage and loss stiffness and moduli from a single SPM scan 3D OmniProbe – Provides forces up to 10 N and scratch lengths up to 150 mm for depth- sensing micro-indentation and tribological studies

-

nanoECR – Conductive nanoindentation system capable of providing simultaneaous in-situ electrical and mechanical measurements for investigating material deformation and stress induced transformation behavior

-

Thermal control – Heating/cooling stages can be added for the investigation of mechanical properties at non-ambient temperatures

-

Vacuum stage – Wafer mounting system that eliminates necessity of gluing or cutting wafers prior to testing

-

Long probes that allow to safely investigate the mechanical properties of samples imersed in water.

Reference: http://www.hysitron.com/products/ti-series/ti-950-triboindenter

Photo during testing of a sample immersed in water.

Development of the scanning probe microscopy (SPM) data analysis software, Gwyddion

The open source software Gwyddion is developed in close collaboration with the CEITEC RG Development of Methods for Analysis and Measuring and a large number of participants from other institutions throughout the world. It has become a standard software in the field and is used by thousands of scientists.

SELECTED PUBLICATIONS

2017

- BANNOV, AG; PRASEK, J; JASEK, O; ZAJICKOVA, L, 2017:Investigation of Pristine Graphite Oxide as Room-Temperature Chemiresistive Ammonia Gas Sensing Material. SENSORS 17 (2)

- BOSTROM, J; SRAMKOVA, Z; SALASOVA, A; JOHARD, H; MAHDESSIAN, D; FEDR, R; MARKS, C; MEDALOVA, J; SOUCEK, K; LUNDBERG, E; LINNARSSON, S; BRYJA, V; SEKYROVA, P; ALTUN, M; ANDANG, M, 2017:Comparative cell cycle transcriptomics reveals synchronization of developmental transcription factor networks in cancer cells. PLOS ONE 12 (12)

- MANAKHOV, A; CECHAL, J; MICHLICEK, M; SHTANSKY, DV, 2017:Determination of NH2 concentration on 3-aminopropyl tri-ethoxy silane layers and cyclopropylamine plasma polymers by liquid-phase derivatization with 5-iodo 2-furaldehyde. APPLIED SURFACE SCIENCE 414 , p. 390 - 397.

- MANAKHOV, A; KEDRONOVA, E; MEDALOVA, J; CERNOCHOVA, P; OBRUSNIK, A; MICHLICEK, M; SHTANSKY, DV; ZAJICKOVA, L, 2017:Carboxyl-anhydride and amine plasma coating of PCL nanofibers to improve their bioactivity. MATERIALS & DESIGN 132 , p. 257 - 265.

- MANAKHOV, A; LANDOVA, M; MEDALOVA, J; MICHLICEK, M; POLCAK, J; NECAS, D; ZAJICKOVA, L, 2017:Cyclopropylamine plasma polymers for increased cell adhesion and growth. PLASMA PROCESSES AND POLYMERS 14 (7)

- MANAKHOV, A;, MICHLICEK, M; FELTEN, A; PIREAUX, J J; NECAS, D; ZAJICKOVA, L., 2017:XPS depth profiling of derivatized amine and anhydride plasma polymers: Evidence of limitations of the derivatization approach. APPLIED SURFACE SCIENCE (394), p. 578 - 585.

- OBRUSNIK, A; JELINEK, P; ZAJICKOVA, L, 2017:Modelling of the gas flow and plasma co-polymerization of two monomers in an atmospheric-pressure dielectric barrier discharge. SURFACE & COATINGS TECHNOLOGY 314 , p. 139 - 147.

2016

- ARJUNAN, KP; OBRUSNIK, A; JONES, BT; ZAJICKOVA, L; PTASINSKA, S, 2016:Effect of Additive Oxygen on the Reactive Species Profile and Microbicidal Property of a Helium Atmospheric Pressure Plasma Jet. Plasma Processes and Polymers 13 (11), p. 1089 - 1105.

- HEGEMANN, D; MICHLICEK, M; BLANCHARD, NE; SCHUTZ, U; LOHMANN, D; VANDENBOSSCHE, M; ZAJICKOVA, L; DRABIK, M, 2016:Deposition of Functional Plasma Polymers Influenced by Reactor Geometry in Capacitively Coupled Discharges. PLASMA PROCESSES AND POLYMERS 13 (2), p. 279 - 286.

- MAKHNEVA, E; MANAKHOV, A; SKLADAL, P; ZAJICKOVA, L, 2016:Development of effective QCM biosensors by cyclopropylamine plasma polymerization and antibody immobilization using cross-linking reactions. SURFACE & COATINGS TECHNOLOGY 290 , p. 116 - 123.

- MANAKHOV, A; MAKHNEVA, E; SKLADAL, P; NECAS, D; CECHAL, J; KALINA, L; ELIAS, M; ZAJICKOVA, L, 2016:The robust bio-immobilization based on pulsed plasma polymerization of cyclopropylamine and glutaraldehyde coupling chemistry. APPLIED SURFACE SCIENCE 360 , p. 28 - 36.

- MANAKHOV, A; MICHLICEK, M; NECAS, D; POLCAK, J; MAKHNEVA, E; ELIAS, M; ZAJICKOVA, L, 2016:Carboxyl-rich coatings deposited by atmospheric plasma co-polymerization of maleic anhydride and acetylene. SURFACE & COATINGS TECHNOLOGY 295 , p. 37 - 45.

- NECAS, D; OHLIDAL, I; FRANTA, D; OHLIDAL, M; VODAK, J, 2016:Simultaneous determination of optical constants, local thickness and roughness of ZnSe thin films by imaging spectroscopic reflectometry. JOURNAL OF OPTICS 18 (1)

- OBRUSNIK, A; SYNEK, P; HUBNER, S; VAN DER MULLEN, JJAM; ZAJICKOVA, L; NIJDAM, S, 2016:Coherent and incoherent Thomson scattering on an argon/hydrogen microwave plasma torch with transient behaviour. PLASMA SOURCES SCIENCE & TECHNOLOGY 25 (5)

- SCHAFER, J; HNILICA, J; SPERKA, J; QUADE, A; KUDRLE, V; FOEST, R; VODAK, J; ZAJICKOVA, L, 2016:Tetrakis(trimethylsilyloxy)silane for nanostructured SiO2-like films deposited by PECVD at atmospheric pressure. SURFACE & COATINGS TECHNOLOGY 295 , p. 112 - 118.

- SOBOTA, A; GUAITELLA, O; SRETENOVIC, GB; KRSTIC, IB; KOVACEVIC, VV; OBRUSNIK, A; NGUYEN, YN; ZAJICKOVA, L; OBRADOVIC, BM; KURAICA, MM, 2016:Electric field measurements in a kHz-driven He jet-the influence of the gas flow speed. PLASMA SOURCES SCIENCE & TECHNOLOGY 25 (6)

- STRBKOVA, L; MANAKHOV, A; ZAJICKOVA, L; STOICA, A; VESELY, P; CHMELIK, R, 2016:The adhesion of normal human dermal fibroblasts to the cyclopropylamine plasma polymers studied by holographic microscopy. SURFACE & COATINGS TECHNOLOGY 295 , p. 70 - 77.

- VORAC, J; POTOCNAKOVA, L; SYNEK, P; HNILICA, J; KUDRLE, V, 2016:Gas mixing enhanced by power modulations in atmospheric pressure microwave plasma jet. PLASMA SOURCES SCIENCE & TECHNOLOGY 25 (2)

2015

- ELIAS, M; KLOC, P; JASEK, O; MAZANKOVA, V; TRUNEC, D; HRDY, R; ZAJICKOVA, L, 2015:Atmospheric pressure barrier discharge at high temperature: Diagnostics and carbon nanotubes deposition. JOURNAL OF APPLIED PHYSICS 117 (10)

- FRANTA, D; NECAS, D; OHLIDAL, I, 2015:Universal dispersion model for characterization of optical thin films over a wide spectral range: application to hafnia. APPLIED OPTICS 54 (31), p. 9108 - 9119.

- FRANTA, D; NECAS, D; OHLIDAL, I; GIGLIA, A, 2015:Dispersion model for optical thin films applicable in wide spectral range. OPTICAL SYSTEMS DESIGN 2015: OPTICAL FABRICATION, TESTING, AND METROLOGY V 9628

- FRANTA, D; NECAS, D; OHLIDAL, I; JANKUJ, J, 2015:Wide spectral range characterization of antireflective coatings and their optimization. OPTICAL SYSTEMS DESIGN 2015: OPTICAL FABRICATION, TESTING, AND METROLOGY V 9628

- KEDRONOVA, E; ZAJICKOVA, L; HEGEMANN, D; KLIMA, M; MICHLICEK, M; MANAKHOV, A, 2015:Plasma Enhanced CVD of Organosilicon Thin Films on Electrospun Polymer Nanofibers. PLASMA PROCESSES AND POLYMERS 12 (11), p. 1231 - 1243.

- MAJZLIKOVA, P; SEDLACEK, J; PRASEK, J; PEKAREK, J; SVATOS, V; BANNOV, AG; JASEK, O; SYNEK, P; ELIAS, M; ZAJICKOVA, L; HUBALEK, J, 2015:Sensing Properties of Multiwalled Carbon Nanotubes Grown in MW Plasma Torch: Electronic and Electrochemical Behavior, Gas Sensing, Field Emission, IR Absorption. SENSORS 15 (2), p. 2644 - 2661.

- MANAKHOV, A; NECAS, D; CECHAL, J; PAVLINAK, D; ELIAS, M; ZAJICKOVA, L, 2015:Deposition of stable amine coating onto polycaprolactone nanofibers by low pressure cyclopropylamine plasma polymerization. THIN SOLID FILMS 581 , p. 7 - 13.

- NECAS, D; VODAK, J; OHLIDAL, I; OHLIDAL, M; MAJUMDAR, A; ZAJICKKOVA, L, 2015:Simultaneous determination of dispersion model parameters and local thickness of thin films by imaging spectrophotometry. APPLIED SURFACE SCIENCE 350 , p. 149 - 155.

- POTOCNAKOVA, L; SPERKA, J; ZIKAN, P; VAN LOON, JJWA; BECKERS, J; KUDRLE, V, 2015:Gravity effects on a gliding arc in four noble gases: from normal to hypergravity. PLASMA SOURCES SCIENCE & TECHNOLOGY 24 (2)

- SYNEK, P; OBRUSNIK, A; HUBNER, S; NIJDAM, S; ZAJICKOVA, L, 2015:On the interplay of gas dynamics and the electromagnetic field in an atmospheric Ar/H-2 microwave plasma torch. PLASMA SOURCES SCIENCE & TECHNOLOGY 24 (2)

2014

- DAVID, B; PIZUROVA, N; SYNEK, P; KUDRLE, V; JASEK, O; SCHNEEWEISS, O, 2014:epsilon-Fe2O3 nanoparticles synthesized in atmospheric-pressure microwave torch. MATERIALS LETTERS 116 , p. 370 - 373.

- DAVID, B; SCHNEEWEISS, O; PIZUROVA, N; REK, A; KUDRLE, V; JASEK, O, 2014:Nanocrystalline alpha-Fe Layer Examined by Mossbauer Spectrometry. ACTA PHYSICA POLONICA A 126 (1), p. 94 - 95.

- FRANTA, D; NECAS, D; ZAJICKOVA, L; OHLIDAL, I, 2014:Broadening of dielectric response and sum rule conservation. THIN SOLID FILMS 571 , p. 496 - 501.

- FRANTA, D; NECAS, D; ZAJICKOVA, L; OHLIDAL, I, 2014:Dispersion model of two-phonon absorption: application to c-Si. OPTICAL MATERIALS EXPRESS 4 (8), p. 1641 - 1656.

- FRANTA, D; NECAS, D; ZAJICKOVA, L; OHLIDAL, I, 2014:Utilization of the sum rule for construction of advanced dispersion model of crystalline silicon containing interstitial oxygen. THIN SOLID FILMS 571 , p. 490 - 495.

- KLAPETEK, P; NECAS, D, 2014:Independent analysis of mechanical data from atomic force microscopy. MEASUREMENT SCIENCE & TECHNOLOGY 25 (4)

- MAJZLIKOVA, P; PRASEK, J; ELIAS, M; JASEK, O; PEKAREK, J; HUBALEK, J; ZAJICKOVA, L, 2014:Comparison of different modifications of screen-printed working electrodes of electrochemical sensors using carbon nanotubes and plasma treatment. PHYSICA STATUS SOLIDI A-APPLICATIONS AND MATERIALS SCIENCE 211 (12), p. 2756 - 2764.

- MANAKHOV, A; SKLADAL, P; NECAS, D; CECHAL, J; POLCAK, J; ELIAS, M; ZAJICKOVA, L, 2014:Cyclopropylamine plasma polymers deposited onto quartz crystal microbalance for biosensing application. PHYSICA STATUS SOLIDI A-APPLICATIONS AND MATERIALS SCIENCE 211 (12), p. 2801 - 2808.

- MANAKHOV, A; ZAJICKOVA, L; ELIAS, M; CECHAL, J; POLCAK, J; HNILICA, J; BITTNEROVA, S; NECAS, D, 2014:Optimization of Cyclopropylamine Plasma Polymerization toward Enhanced Layer Stability in Contact with Water. PLASMA PROCESSES AND POLYMERS 11 (6), p. 532 - 544.

- NECAS, D; CUDEK, V; VODAK, J; OHLIDAL, M; KLAPETEK, P; BENEDIKT, J; RUGNER, K; ZAJICKOVA, L, 2014:Mapping of properties of thin plasma jet films using imaging spectroscopic reflectometry. MEASUREMENT SCIENCE & TECHNOLOGY 25 (11)

- NECAS, D; OHLIDAL, I, 2014:Consolidated series for efficient calculation of the reflection and transmission in rough multilayers. OPTICS EXPRESS 22 (4), p. 4499 - 4515.

- NECAS, D; OHLIDAL, I; FRANTA, D; CUDEK, V; OHLIDAL, M; VODAK, J; SLADKOVA, L; ZAJICKOVA, L; ELIAS, M; VIZD'A, F, 2014:Assessment of non-uniform thin films using spectroscopic ellipsometry and imaging spectroscopic reflectometry. THIN SOLID FILMS 571 , p. 573 - 578.

- VORAC, J; OBRUSNIK, A; PROCHAZKA, V; DVORAK, P; TALABA, M, 2014:Spatially resolved measurement of hydroxyl radical (OH) concentration in an argon RF plasma jet by planar laser-induced fluorescence. PLASMA SOURCES SCIENCE & TECHNOLOGY 23 (2)

2013

- FRANTA, D; NECAS, D; ZAJICKOVA, L, 2013:Application of Thomas-Reiche-Kuhn sum rule to construction of advanced dispersion models. THIN SOLID FILMS 534 , p. 432 - 441.

- FRANTA, D; NECAS, D; ZAJICKOVA, L; OHLIDAL, I; STUCHLIK, J, 2013:Advanced modeling for optical characterization of amorphous hydrogenated silicon films. THIN SOLID FILMS 541 , p. 12 - 16.

- FRANTA, D; NECAS, D; ZAJICKOVA, L; OHLIDAL, I; STUCHLIK, J; CHVOSTOVA, D, 2013:Application of sum rule to the dispersion model of hydrogenated amorphous silicon. THIN SOLID FILMS 539 , p. 233 - 244.

- NECAS, D; FRANTA, D; OHLIDAL, I; PORUBA, A; WOSTRY, P, 2013:Ellipsometric characterization of inhomogeneous non-stoichiometric silicon nitride films. SURFACE AND INTERFACE ANALYSIS 45 (7), p. 1188 - 1192.

- NECAS, D; KLAPETEK, P, 2013:One-dimensional autocorrelation and power spectrum density functions of irregular regions. ULTRAMICROSCOPY 124 , p. 13 - 19.

- SPERKA, J; SOUCEK, P; VAN LOON, JJWA; DOWSON, A; SCHWARZ, C; KRAUSE, J; KROESEN, G; KUDRLE, V, 2013:Hypergravity effects on glide arc plasma. EUROPEAN PHYSICAL JOURNAL D 67 (12)

- ZAJICKOVA, L; ELIAS, M; BURSIKOVA, V; STUDYNKOVA, Z; MAZANKOVA, V; MICHLICEK, M; HOUDKOVA, J, 2013:Low pressure plasmachemical processing of multi-walled carbon nanotubes for the production of polyurethane composite films with improved mechanical properties. THIN SOLID FILMS 538 , p. 7 - 15.

2012

- BANNOV, AG; UVAROV, NF; UKHINA, AV; CHUKANOV, IS; DYUKOVA, KD; KUVSHINOV, GG, 2012:Structural changes in carbon nanofibers induced by ball milling. CARBON 50 (3), p. 1090 - 1098.

- BANNOV, AG; VARENTSOV, VK; CHUKANOV, IS; GORODILOVA, EV; KUVSHINOV, GG, 2012:Comparative analysis of methods of oxidative modification of carbon nanofibers. PROTECTION OF METALS AND PHYSICAL CHEMISTRY OF SURFACES 48 (2), p. 199 - 206.

- DAVID, B; PIZUROVA, N; SCHNEEWEISS, O; SANTAVA, E; KUDRLE, V; JASEK, O, 2012:gamma-Fe2O3 Nanopowders Synthesized in Microwave Plasma and Extraordinarily Strong Temperature Influence on Their Mossbauer Spectra. JOURNAL OF NANOSCIENCE AND NANOTECHNOLOGY 12 (12), p. 9277 - 9285.

- DAVID, B; SCHNEEWEISS, O; SANTAVA, E; JASEK, O, 2012:Magnetic Properties of gamma-Fe2O3 Nanopowder Synthesized by Atmospheric Microwave Torch Discharge. ACTA PHYSICA POLONICA A 122 (1), p. 9 - 11.

- MANAKHOV, A; MORENO-COURANJOU, M; BOSCHER, ND; ROGE, V; CHOQUET, P; PIREAUX, JJ, 2012:Atmospheric Pressure Pulsed Plasma Copolymerisation of Maleic Anhydride and Vinyltrimethoxysilane: Influence of Electrical Parameters on Chemistry, Morphology and Deposition Rate of the Coatings. PLASMA PROCESSES AND POLYMERS 9 (4), p. 435 - 445.

- SCHAFER, J; FOEST, R; REUTER, S; KEWITZ, T; SPERKA, J; WELTMANN, KD, 2012:Laser schlieren deflectometry for temperature analysis of filamentary non-thermal atmospheric pressure plasma. REVIEW OF SCIENTIFIC INSTRUMENTS 83 (10)

2011

- BURSIKOVA, V; KUCEROVA, Z; ZAJICKOVA, L; JASEK, O; KUDRLE, V; MATEJKOVA, J; SYNEK, P, 2011:MEASUREMENT OF MECHANICAL PROPERTIES OF COMPOSITE MATERIALS. CHEMICKE LISTY 105 , p. S171 - S174.

- DAVID, B; PIZUROVA, N; SCHNEEWEISS, O; KUDRLE, V; JASEK, O; SYNEK, P, 2011:Iron-Based Nanopowders Containing alpha-Fe, Fe3C, and gamma-Fe Particles Synthesised in Microwave Torch Plasma and Investigated with Mossbauer Spectroscopy. JAPANESE JOURNAL OF APPLIED PHYSICS 50 (8)

- FRANTA, D; NECAS, D; ZAJICKOVA, L; BURSIKOVA, V; COBET, C, 2011:Combination of synchrotron ellipsometry and table-top optical measurements for determination of band structure of DLC films. THIN SOLID FILMS 519 (9), p. 2694 - 2697.

- KLAPETEK, P; VALTR, M; NECAS, D; SALYK, O; DZIK, P, 2011:Atomic force microscopy analysis of nanoparticles in non-ideal conditions. NANOSCALE RESEARCH LETTERS 6

- MANAKHOV, A; MORENO-COURANJOU, M; CHOQUET, P; BOSCHER, ND; PIREAUX, JJ, 2011:Diene functionalisation of atmospheric plasma copolymer thin films. SURFACE & COATINGS TECHNOLOGY 205 , p. S466 - S469.

- PRASEK, J; DRBOHLAVOVA, J; CHOMOUCKA, J; HUBALEK, J; JASEK, O; ADAM, V; KIZEK, R, 2011:Methods for carbon nanotubes synthesis-review. JOURNAL OF MATERIALS CHEMISTRY 21 (40), p. 15872 - 15884.

- SYNEK, P; JASEK, O; ZAJICKOVA, L; DAVID, B; KUDRLE, V; PIZUROVA, N, 2011:Plasmachemical synthesis of maghemite nanoparticles in atmospheric pressure microwave torch. MATERIALS LETTERS 65 (6), p. 982 - 984.

- ZAJICKOVA, L; FRANTA, D; NECAS, D; BURSIKOVA, V; MURESAN, M; PERINA, V; COBET, C, 2011:Dielectric response and structure of amorphous hydrogenated carbon films with nitrogen admixture. THIN SOLID FILMS 519 (13), p. 4299 - 4308.

2010

- MURESAN, MG; ZAJICKOVA, L; BURSIKOVA, V; FRANTA, D; NECAS, D, 2010:PREPARATION AND CHARACTERIZATION OF DLC:N FILMS. NANOCON 2010, 2ND INTERNATIONAL CONFERENCE , p. 434 - 440.

- SCHNEEWEISS, O; DAVID, B; JASEK, O; ZAJICKOVA, L; VONDRACEK, M; ZBORIL, R; MASLAN, M, 2010:Mossbauer Effect Study of Iron Thin Films on Si/SiO(x) Substrate and Iron Phases at Deposited Carbon Nanotubes. MOSSBAUER SPECTROSCOPY IN MATERIALS SCIENCE - 2010 1258 , p. 90 - 95.

All publications are available at http://publications.physics.muni.cz/author/ceitec

To download fulltext, use login: guest , password: guest

In our numerical models, we focus exclusively on plasma devices which have direct material or biomedical applications. We simulate plasma in close-to-real geometries in relevant gas mixtures. This does, sometimes, pose a big challenge because the coupling of the plasma, the gas dynamics and mixing and the electromagnetic field is very strong. The numerical modelling is, always, complemented with plasma diagnostics in order to verify the validity of our models. The most interesting models that we have developed include:

In our numerical models, we focus exclusively on plasma devices which have direct material or biomedical applications. We simulate plasma in close-to-real geometries in relevant gas mixtures. This does, sometimes, pose a big challenge because the coupling of the plasma, the gas dynamics and mixing and the electromagnetic field is very strong. The numerical modelling is, always, complemented with plasma diagnostics in order to verify the validity of our models. The most interesting models that we have developed include: Knowing the conditions in the plasma discharges, especially the gas and electron temperatures and the electron density) is absolutely crucial for transferring our plasma processes to different setups or for upscaling them. In addition, measurements of plasma properties are very useful for validation of the numerical models developed in our group. So far, we have employed the following techniques to characterize our discharges:

Knowing the conditions in the plasma discharges, especially the gas and electron temperatures and the electron density) is absolutely crucial for transferring our plasma processes to different setups or for upscaling them. In addition, measurements of plasma properties are very useful for validation of the numerical models developed in our group. So far, we have employed the following techniques to characterize our discharges:

A unique normal-incidence imaging spectrophotometer in UV-visible-NIR spectral range with spatial resolution of 37 µm was built at

A unique normal-incidence imaging spectrophotometer in UV-visible-NIR spectral range with spatial resolution of 37 µm was built at  The Hysitron TI 950 TriboIndenter is a nanomechanical test instrument with a high degree of sensitivity and excellent performance. Its Advanced Control Module improves the precision of feedback-controlled nanomechanical testing, provides dual head testing capability for nano/micro scale connectivity, and offers very good noise floor performance. Several different nanomechanical testing techniques are currently possible, making the TI 950 nano-indenter system an effective nanomechanical characterization tool for a wide range of applications.

The Hysitron TI 950 TriboIndenter is a nanomechanical test instrument with a high degree of sensitivity and excellent performance. Its Advanced Control Module improves the precision of feedback-controlled nanomechanical testing, provides dual head testing capability for nano/micro scale connectivity, and offers very good noise floor performance. Several different nanomechanical testing techniques are currently possible, making the TI 950 nano-indenter system an effective nanomechanical characterization tool for a wide range of applications.

Notable features of Gwyddion include:

Notable features of Gwyddion include: The development of Gwyddion is naturaly connected to development of data processing methods in SPM. Examples includes methods for the analysis of

The development of Gwyddion is naturaly connected to development of data processing methods in SPM. Examples includes methods for the analysis of