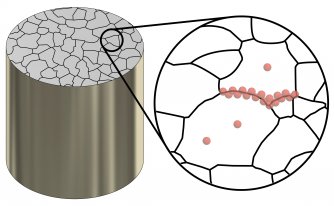

Low cohesion of materials may result, for example, in a sudden collapse of a metallic structure, as it happened e.g. during the rotor rupture in the Hinkley Point A power plant in 1969. “This so-called intergranular brittleness is often caused by impurities or trace elements that can never be completely removed during the production of the given material. They accumulate in the space between individual crystallites, called also grains. Due to this phenomenon, the material cohesion can be significantly reduced, causing a sudden failure of the material when exposed to stress,” says one of the authors of this publication, professor Mojmír Šob from the research group Synthesis and Analysis of Nanostructures at the CEITEC MU.

Intergranular failure is very difficult to predict. Therefore, scientists attempt not only to explain its reasons in detail, but also to formulate methods allowing the estimates of impacts of the presence of impurities on brittleness of technologically important materials.

“For metallic materials, sulphur and phosphorus are the most harmful solutes, but the mechanical properties are significantly impaired also by elements like lead or bismuth. These impurities tend to segregate at the grain boundaries, because this process lowers the total energy of the system. However, grain boundaries are weak spots within the material structure and if other substances accumulate there, the interatomic bonds change, which results in most cases in significant weakening of the material cohesion,” professor Šob explains.

The research group of prof. Šob has been engaged in this problem for a long time and the collaboration with the colleagues from the Institute of Physics of the Academy of sciences of the Czech Republic in Prague was very fruitful. Together they have obtained a number of original findings, for example on magnetism of grain boundaries or on the dependence of the impurity segregation on the grain boundary orientation. “In Brno, we focus on theoretical research, simulating the material structure in the computer and modelling its various properties. On the other hand, our colleagues from the Institute of Physics conduct predominantly experimental research,” professor Šob explains.

In the above-mentioned paper, they have collected and critically assessed the values of segregation energies of a large number of impurities in iron, nickel and aluminium at the grain boundaries and surfaces. These values were obtained not only from their own calculations and experiments, but they also included data available in the literature. “In the case of such data, we analysed under what conditions and through which methods they were obtained and to what extent are they reliable,” professor Šob adds, pointing out that the results of this basic research can also be used by researchers investigating new possibilities in metal processing. The methods and approaches employed in this paper may be applied also for other materials.

In conclusion, let us note that this success is even more valuable due to the fact that the team of the Czech authors published this paper without a co-authorship of an outstanding expert from a prestigious Western scientific institution who would serve as a “door opener”. On the contrary, the paper comes exclusively from the domestic authors. For prof. Šob, it is already his third paper published in this prestigious scientific journal during last seven years.

Bibliographic data of the article are as follows:

P. Lejček, M. Šob, V. Paidar: Interfacial segregation and grain boundary embrittlement: An overview and critical assessment of experimental data and calculated results. Progress in Materials Science 87 (2017) 83–139